STOL CONE

PRODUCT GENERATIONS

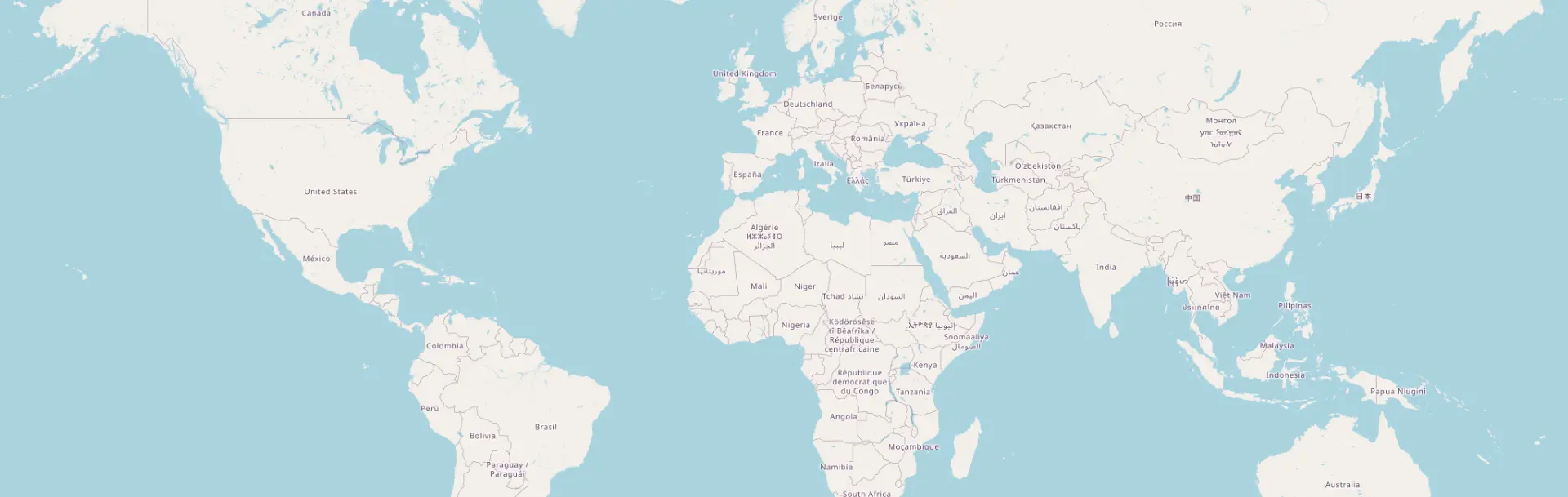

Stol Cone - PRO model

Maximum load capacity

Stability limit

Made of recycled plastic

Maximum load-bearing capacity

Stol Cone - ECO model

Maximum load capacity

Stability limit

Made of recycled plastic

Maximum load-bearing capacity

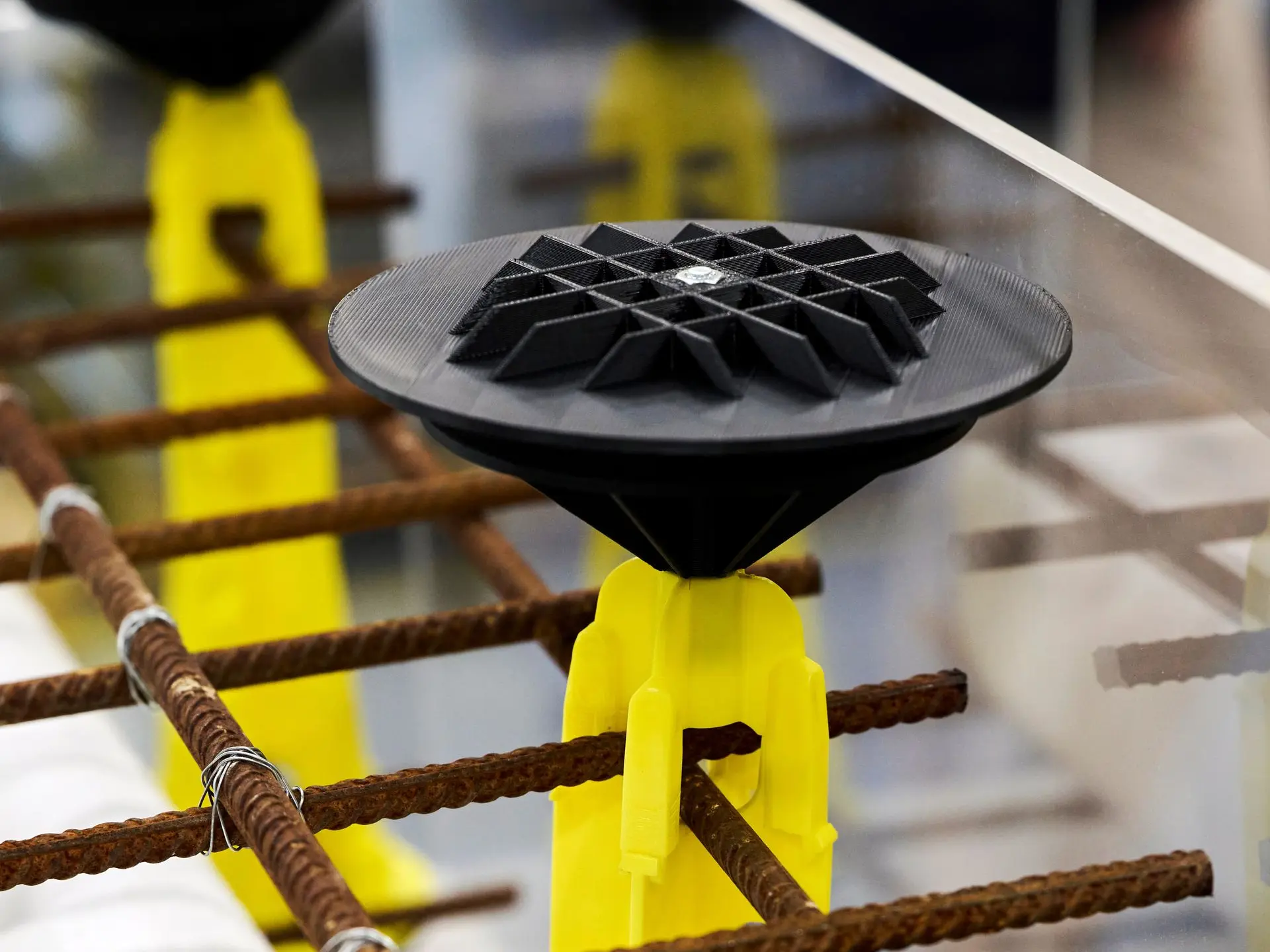

THE SPACER SYSTEM

OF THE FUTURE

IN THE

CONSTRUCTION INDUSTRY

Stol Cone is an innovative, eco-friendly spacer system designed to meet the needs of the modern construction industry. This product was developed to provide an effective solution for enhancing the stability and support of concrete structures, while improving workflow efficiency and reducing environmental impact.

Stol Cone consists of three core components: base element, middle element, and top element — all of which can be interconnected, ensuring flexible and fast installation.

WHAT YOU CAN EXPECT FROM US

MORE THAN JUST A SPACER PRODUCT

The Spacer Cone represents an entirely new construction approach, so called internal grid construction method. This system provides a high level of control over building dimensions. Additional product families, such as partition walls, raised floors, and suspended ceilings, can connect to the core spacer product, forming an interconnected system. One of its key principles is 'poka-yoke', which ensures error-proof usage by eliminating incorrect application.

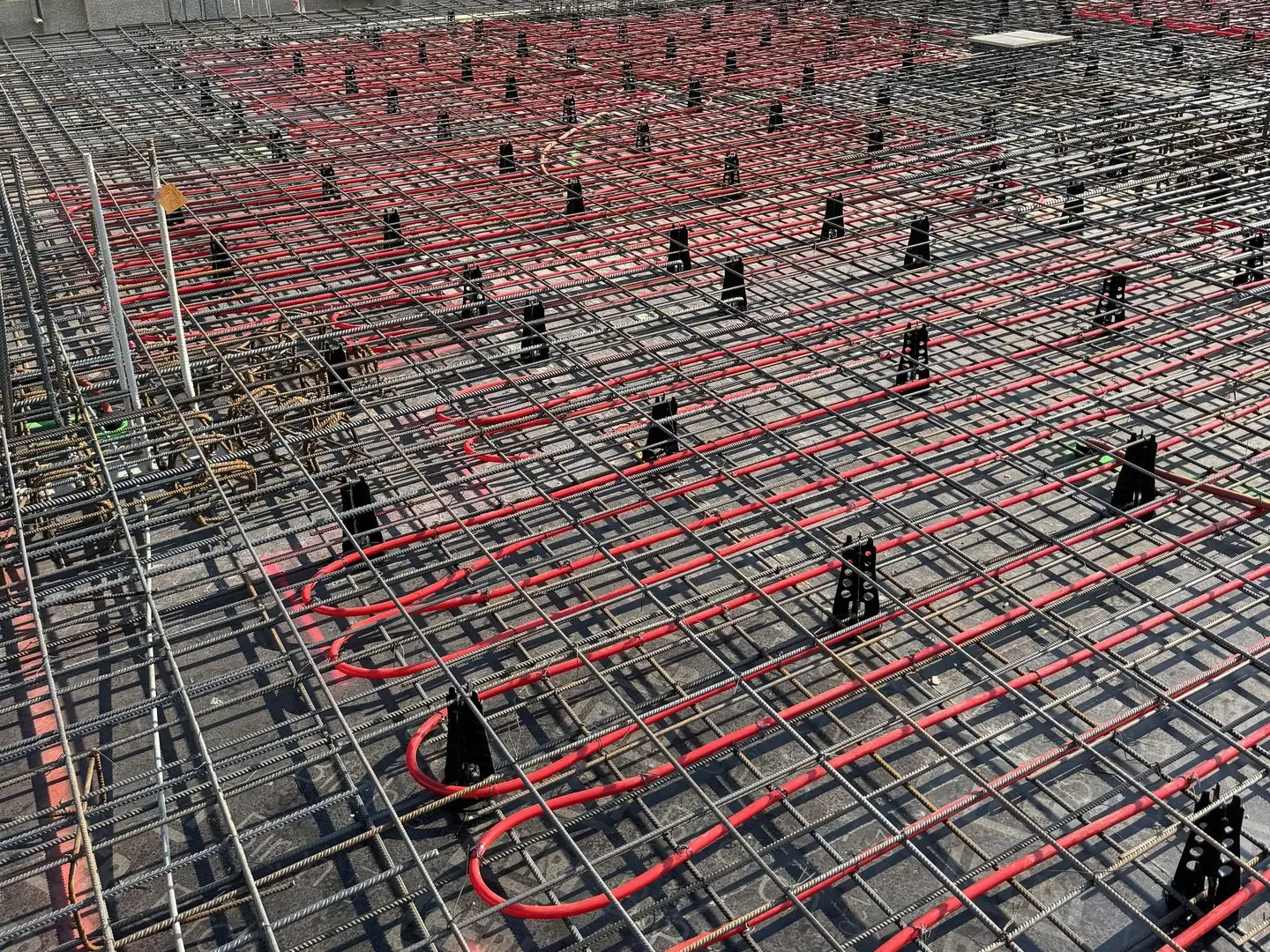

8X BIGGER, MORE SUSTAINABLE LOGISTICAL EFFICIENCY

A single truckload of Spacer Cone products weighs 10,829 kg and has a volume of 61 m3, enabling the construction of 64,000 m2 of area - achieving approx. 8 times bigger efficiency compared to alternative systems. This optimization reduces transportation costs and CO2 emissions while minimizing fuel consumption.

UP TO 10% COST SAVINGS

By using recycled plastic instead of steel, manufacturing costs are significantly reduced. Our products also enable quantifiable savings in construction costs, driven by increased efficiency, faster and simpler installation, and reduced need for specialized expertise. Due to optimized geometries, logistics costs are significantly lower, too, as our products are designed for maximum space utilization with neatly arranged packaging for efficient

THREE ELEMENTS, SEVERAL FUNCTIONS

BASE ELEMENT

This element ensures the spacing of the lower reinforcement, separating the rebar from the formwork and thus maintaining the structural integrity of the slab. It is highly stable and includes connection points to support the attachment of the other elements.

MIDDLE ELEMENT

This element ensures upper reinforcement spacing, guaranteeing that the rebar remains in the correct position during concreting. Thanks to its modular design, it is available in various heights, making it suitable for slabs of different thicknesses.

TOP ELEMENT

Functioning as the finishing component of the structure, it defines the final height and provides protection for the upper reinforcement.

GREEN SOLUTION, FASTER CONSTRUCTION

THANKS TO OUR INNOVATIVE TECHNOLOGY

ECO-FRIENDLY MATERIAL USAGE

Made from 100% recycled plastic, it reduces construction waste and supports sustainable building practices.

EFFICIENT INSTALLATION

The Stol Cone system is easy to assemble, resulting in significant time savings on-site. Fast assembly enables shorter project timelines, thereby reducing overall project costs.

APPLICATION BENEFITS

THAT

SIMPLIFY CONSTRUCTION

COST EFFICIENCY

Due to fast installation and reduced labor requirements, Stol Cone delivers significant cost savings.

TIME SAVINGS

The simplicity and speed of the installation process greatly reduce overall project duration.

STABILITY AND SAFETY

The system's design ensures precise positioning of reinforcement and the reliability of concrete structures.

MEETING HIGH-QUALITY STANDARDS

TO ENSURE YOUR PROJECTS FULLY COMPLY WITH MODERN CONSTRUCTION INDUSTRY REQUIREMENTS

VERSATILE AND INNOVATIVE SOLUTION

- Multiple functions in a single product lower spacer, upper spacer, concrete thickness marker

- Usable in all weather conditions not sensitive to temperature

- Applicable to sloped structures without the need for additional formwork

- Equipped with built-in connection points for other structural elements, e.g. ceilings

- Allows for mechanical cable routing reducing the need for post-installation work

-

Easily calculable quantity per project decreasing the workload of site supervisors

COST AND TIME SAVINGS

- Faster reinforcement placement reduces labor time and costs, even from the first use

- Fewer measuring points needed thanks to the grid system, saving time and improving orientation at connection points

- No need for laser leveling, as the product system indicates the concrete pouring plane

- Fewer fasteners required due to its multifunctional design

- Easy and quick to install, it can be used even by less skilled labor

-

Up to 10% cost savings achievable by reducing manufacturing, construction, and logistics expenses

STABILITY AND SAFETY

- 4-point fastening system with up to 2 kN load capacity, increasing the structural stability

- Prevents reinforcement displacement, extending the lifespan of the structure

- Ensures uniform concrete layer thickness, enhancing structural integrity

- Reduces the risk of incorrect installation, as it fits precisely into the construction process

-

Enables safer working conditions, lowering the risk of workplace accidents

SIMPLIFIED LOGISTICS AND INSTALLATION

- Compact design, it takes up less space, reducing transportation costs

- Modular system, easily combinable with other Spacer Cone products

- Each product is easy to store and organize, enabling faster on-site execution

-

8–10 times lower logistics costs as a result

ENVIRONMENTALLY FRIENDLY AND SUSTAINABLE

- Made from 100% recycled plastic, reducing the amount of waste

- Less concrete usage, resulting in lower CO₂ emissions

- Reusable and durable, minimizing construction waste

-

Supports the circular economy by using only recycled materials

We offer Solutions in Structure Engineering and Beyond

You can easily defeat all challenges with SpacerCone’s solutions for the construction industry, let they be related to execution, cost efficiency, or ensuring precision work. The system’s simplicity and flexibility enable it to be easily used by everyone, ranging between less-trained laborers and professional engineers. By using SpacerCone, you can decrease the necessary labor time, minimize material consumption, and also contribute to decreasing the burden on the environment. Thanks to its innovative form, the system offers reliable solutions in each step of construction. Let them be related to inclined structures, exposed concrete, or complex geometric challenges.

SpacerCone is a modern and efficient spacer, which can be complemented with our additional products. Our further products under development:

- WallCone: Wall spacer

- FloorCone: Our own Reinforced Floor Panel System

- CeilingCone: Our Reinforced Ceiling

- CoverCone: Concrete Protection for the Construction Phase

- ConcreteLight: Weight Relief for Decking

Efficient and economical Solutions with the SpacerCone System

Bottom Spacer (Between the formwork and lower formwork)

Spacer between the lower and upper formwork

MARKING THE THICKNESS OF THE STRUCTURAL CONCRETE

DECREASED CONSTRUCTION TIME AND LABOR COSTS

5-POINT ANCHOR POINT WITH 2 KN CAPACITY

SUPPORTS THE PLACING OF INTERNAL PARTITION WALLS

CAN BE FASTENED WITHOUT THE USE OF NAILS EVEN WITH STRUCTURES OF INCLINED FORMWORKS

INCLINED STRUCTURES CAN BE CONCRETED WITHOUT A COUNTER FORMWORK

COVER CONE FOR FROST, SNOW, RAIN, AND HEAT PROTECTION SYSTEMS

WHAT GUARANTEES OUR RELIABILITY BEYOUND

OUR CREDIBILITY

600 KG LOAD CAPACITY

The spacer cone has reached Technology Readiness Level 9 (TRL), meaning it is fully market-ready and, based on patent analysis, has achieved the peak of its technological development. Certified tests have shown that the product maintains stability up to a load of over 600 kg, whereas current spacers are typically designed for approximately 150 kg.

ETA CERTIFICATION IN PROGRESS

By the end of 2025, the complete product system, which represents a unique and previously non-existent technology on the market, will obtain ETA certification, further supporting its reliability and necessity.

STABILITY VERIFIED BY BETON VEREINIGUNG

The products have been tested not only in simulations and controlled conditions but also in real-world environments. Thanks to the base diameter, they effectively resist lateral forces, and all product systems demonstrate high stability, as confirmed by Betonvereinigung.